Part 4: Perspectives on Safety in Yachting

To see the full schedule click here.

In the past, some have believed that having standard operating procedures (SOPs) in place can actually reduce the level of safety onboard yachts.

I believe this can be true, but only if you blindly follow a checklist without giving any thought to the outcome.

Most seafarers have a level of training that allows them to think but we are all human and, when we stop thinking, mistakes happen.

So as fallible beings, how do we prevent mistakes from happening?

Standard Operating Procedures

Given the size and complexities of modern superyachts, it is simply impossible, not to mention irresponsible, to assume crewmembers can rely solely on their memories to manage and complete every aspect of a yacht’s operation.

Typically a well-run yacht will have over 200 SOPs in their files relating to everything from regulatory compliance to employment requirements to guest cabin and breakfast set-up. Checklists, procedures, equipment inspections, permits, risk assessments, familiarizations, inductions and machinery logs… the list goes on and on.

SOPs provide an operational framework and a foundation for the captain to ensure efficient operations, consistency of service and regulatory compliance, all of which underpin the safety culture onboard.

Yacht Specific SOPs

However, since each yacht is different, it’s vital that SOPs are tailored to each individual yacht. They should also be in place prior to the yacht’s delivery. If they are not, it could be argued that the vessel is unseaworthy and she should not leave the dock until they are.

The problem we see in our industry is a lack of experienced crew who have the knowledge and skills to sit in an office and write procedures and checklists for an operation or space that exists to them only on paper and CAD drawings. And as yachts get larger, operations and systems only become more complex, compounding the issues.

As a cost saver, heads of department (HODs) are seldom employed during a build until the final six months. During this period an HOD is expected to organize and fit out the storage for each space for which they are responsible; order inventory and spare parts; assist in the employment of crew for their department; purchase the safety and fire fighting equipment required to meet flag regulations; log the inventory and planned maintenance for all equipment into the yacht’s management software; collect and collate the Safety Data Sheets for every product on board and... produce hundreds of yacht specific SOPs.

This workload is massive for even the most experienced build crew.

If the yacht's SOPs are not produced to a good standard during the build period, the person it ultimately affects is the owner. Their new yacht never really performs at its best and the crew play catch-up for years. This can lead to the crew feeling that the owner does not put their safety first and that the operation is second-rate. It becomes impossible to create a good onboard safety culture in this environment, and the residue of this build period mistake will be carried with the yacht for years, in some cases for the yacht’s entire life.

The bottom line is this: If there are no yacht-specific SOPs in place then neither the yacht nor the crew can perform at their best.

Safety & Maintenance

Safety and maintenance go hand in hand. For crew to believe in the safety culture onboard, the maintenance culture must be seen to be proactive and reactive, and planned and unplanned maintenance systems should be in place for all departments and be transparent to all HODs.

The use of planned maintenance software can provide an effective framework for this, while regular inspections and testing of equipment serve as leadership tools in creating and reinforcing a strong safety culture onboard.

Crew Numbers

Even with a good maintenance system and SOPs, the yacht still needs the correct number of crew to operate safely.

Some sales brokers will tell the owner that they can run their 50m yacht with 10 crew, or their 70m yacht with 15 crew. Some designers will disregard the functionality of the yacht and provide impossible access to areas that take three people to safely clean. Don’t get me wrong, I’m the first to admire great design and innovation but, if an owner wants to create a masterpiece, the yacht needs to have form and function. A yacht cannot function at its intended best if there are insufficient crew to provide the best service to guests and also maintain the yacht’s condition.

The question is what should take precedence when considering crew numbers? Should it be guest services, maintaining the owner’s investment, or maintaining safe operations?

There are a range of perspectives on this subject, but ultimately the calculation should be based on all of the following three scenarios:

-

Having enough crew to complete daily maintenance will not only keep the yacht looking good it will maintain the yachts overall condition and the owners’ investment.

-

Having enough crew to provide the required level of service day and night while staying within the MLC guidelines will provide the Owner and guests with what they need.

-

Having enough crew to execute the required emergency procedures and permits to work will satisfy the compliance regulations of your Flag.

If there are not enough crew onboard, one or all of these situations will not be satisfied and the yacht will be viewed by the industry as substandard and it will be hard to keep good crew.

The MLC guidelines are a great place to start when calculating crew numbers. For example, if you can’t schedule the total crew to complete their required work within the MLC guidelines when guests are onboard, one of two things needs to happen: Reduce the standards and service OR increase the number of crew.

Owners and Captains

Credibility, honesty and trust are the bases of every good owner/captain relationship. Sometimes owners won’t want to hear what you need to tell them but, if you feel the owner is making a mistake, find a way to tell them so they respect you for it. This is what they pay you for. They pay you to be a decision maker, a leader, a negotiator and a problem solver, and they will genuinely listen to you if you present them with the facts and a thoughtful solution.

Always remember, it's the captain who is in charge of day-to-day operations, and it's the captain who will appear in a court of law when an accident happens.

And if you’re a self-managed yacht, don’t make the mistake of not operating a safety management system just because you’re not required to. Do it because it saves lives and it may just keep you out of jail in the event of an accident.

A Case for Systems Thinking

In a paper from the MCA titled “Just Culture” the author suggests that we need to change how we view safety. We need to move away from the old traditional thinking of simple cause and effect and adopt the modern way of understanding that things happen due to complex system behaviour. This is called “Systems Thinking” and encourages us to see the world as a complex system of interacting relationships which produce both good and bad outcomes.

In a systems thinking environment, people are seen less as a source of error and more as the creators of safety. In reality there will always be gaps in any system because designers and rule makers cannot foresee all situations, so the crew themselves must identify and manage risks that arise and continually improve their SOPs in the process.

Yacht operations are dynamic and issues around safety emerge continuously from the overall behaviour of a yacht’s interacting components, including its people. Crew turnover, scheduling and commercial pressures can also cause a yacht’s operation to drift away from safety.

A solid framework of operating procedures specific to your yacht is an important safeguard. As well as having a positive influence on the performance and morale of the crew, it shapes and reinforces the entire safety culture onboard.

About the Author

David Clarke joined the yachting industry in 1993 as a young 23 year old with five years of sea time already in his log book. As the 5th generation of seafarers in his family he has accumulated over 500,000 nautical miles of cruising in his 27 year career at sea. Having obtained his first Captain's licence at the age of 19, (Class 5) and the MCA 3000 ton licence at the age of 28, David has seen firsthand how the ISM, ISPS and MLC conventions have driven onboard safety to a better place but at the cost of excessive paperwork and administrative burdens.

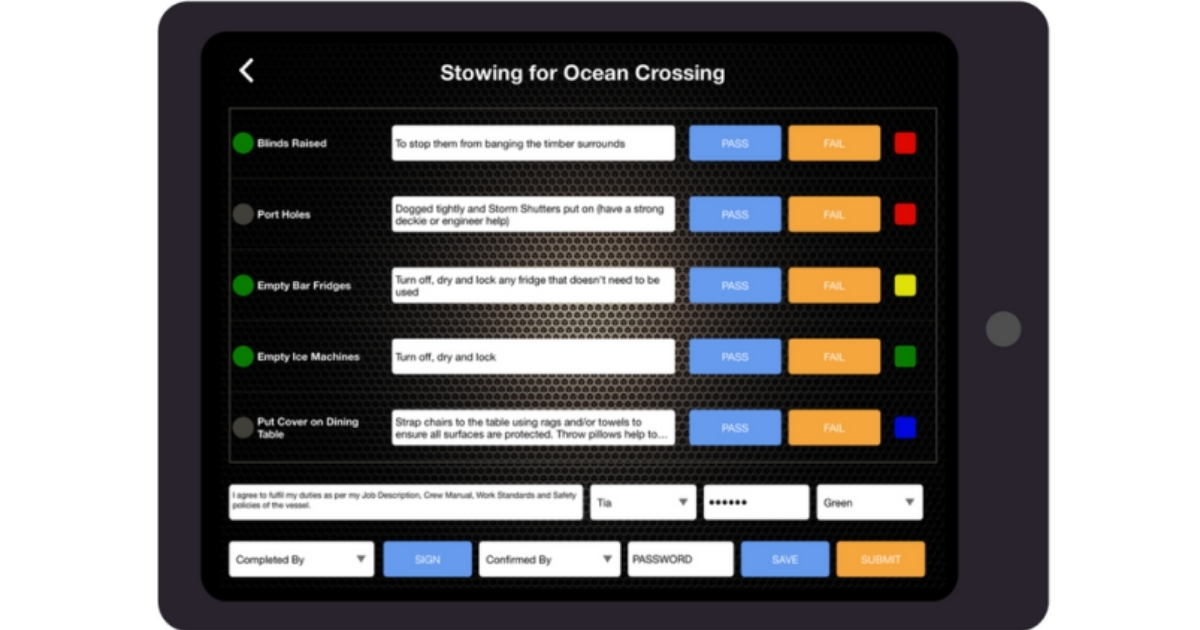

In 2012 David founded Superyacht Operating Systems and published a document library that now provides over 3,000 crew with free access to hundreds of useful onboard procedures and checklists.

In 2016 he launched Total Superyacht Compliance Software which has grown into a full Vessel Management System that automates workflow between departments, a paperless and time-efficient solution for Regulatory Compliance, Planned Maintenance, Inventory and Crew Management.

First published by OnboardOnline on 30th August 2017. Last updated on 14th December 2020.

Post your comment

You cannot post comments until you have logged in.

Login to post a commentComments

No one has commented on this page yet.

RSS feed for comments on this page | RSS feed for all comments